Trending...

- City Of Chicago Joins Illinois Lawsuit Challenging Illegal Actions by Federal Immigration Agents in Chicago

- Chicago: Mayor Brandon Johnson Statement On Trump Revoking Protected Status For Somali Immigrants

- Naperville Police Arrest Plainfield Convicted Felon Allegedly in Possession of a Loaded Gun

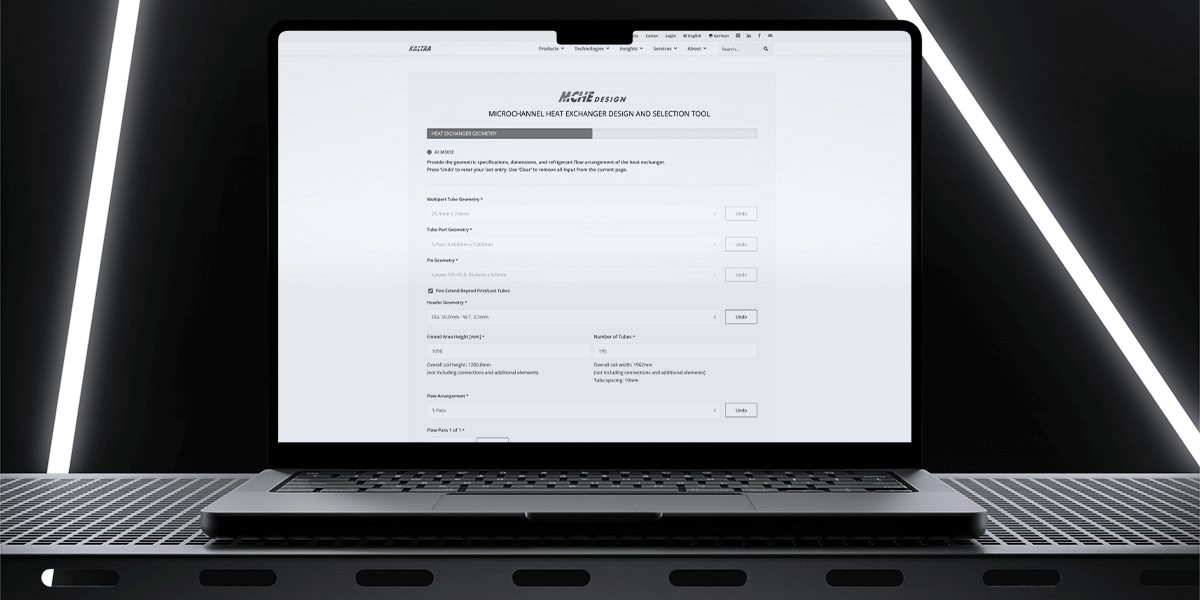

ALTMUNSTER, Austria - illiNews -- Kaltra is proud to announce the release of the next-generation MCHEdesign, now fully integrated with its online coil selection and simulation platform MCHEselect. This major update delivers instant creation of microchannel heat exchanger (MCHE) coil designs, on-the-fly performance simulation — and the ability for users to carry their designs directly into MCHEselect for further simulation under varying conditions.

What's New: Real-Time Simulation + Seamless Coil Workflow

With the updated MCHEdesign, users benefit from:

"This integration closes the loop — engineers can now design, simulate, validate, and iterate MCHE coils all in one place," said Lukas Engelhardt, Business Development Officer at Kaltra. "It dramatically reduces design cycle time, eliminates errors from manual data transfer, and ensures that designs remain within Kaltra's manufacturing capabilities."

More on illi News

Retaining the Core Strengths of MCHEdesign

MCHEdesign continues to offer the two modes introduced earlier:

Thus, users retain flexibility: they can rely on guided design for fast, standard projects, or employ full manual control when needed.

Designs Aligned With Manufacturing Capabilities

A key enhancement in the new MCHEdesign version is the expanded database of microchannel heat exchanger components, including microchannel tubes, fins, tube-fin-manifold combinations and layout variants.

These components and their validated combinations form the foundation for substantial updates to coil design logic, allowing users to explore a broader range of geometries, thermal configurations, and application-specific optimizations. The software ensures that all selectable options remain compatible with Kaltra's engineering standards and production capabilities.

As a result, users can now configure heat exchanger designs that directly leverage Kaltra's latest production capabilities — ensuring that software-generated designs are not only thermodynamically sound but also fully manufacturable without additional engineering adaptation.

From Design to Deployment — Faster, Safer, Smarter

This new integration streamlines the entire MCHE workflow:

This makes MCHEdesign + MCHEselect a complete digital platform for MCHE development — from conception to simulation, validation, and manufacturing.

More on illi News

What This Means for Kaltra Customers

Availability

The integrated MCHEdesign platform is available at the Kaltra website. Existing MCHEdesign users will receive automatic access to the updated version. New users can register via the inquiry form.

What's New: Real-Time Simulation + Seamless Coil Workflow

With the updated MCHEdesign, users benefit from:

- Instant simulation results — as soon as design parameters are entered, results are calculated and displayed in real time.

- Automatic coil creation for MCHEselect — once a design is completed, the coil is created and made immediately available in MCHEselect under a unique model code, enabling further performance simulation or validation under different operating conditions.

- Unified design → simulation → validation workflow — no manual export/import, no data loss, just one continuous pipeline from initial design to advanced performance assessment.

- Support for all major heat-exchanger types — including condensers, evaporators, reversible coils (heat pump mode), and single-phase fluid coils (air-to-fluid), in both parallel-flow and serpentine layouts.

"This integration closes the loop — engineers can now design, simulate, validate, and iterate MCHE coils all in one place," said Lukas Engelhardt, Business Development Officer at Kaltra. "It dramatically reduces design cycle time, eliminates errors from manual data transfer, and ensures that designs remain within Kaltra's manufacturing capabilities."

More on illi News

- Chicago: ICYMI: Mayor Brandon Johnson Builds On Community Safety, Violence, And Overdose Reduction Progress—Blasts Trump Cuts

- Indie Creator Opens the Digi 995 Universe Ahead of Kickstarter Launch

- Chicago: Mayor Brandon Johnson Announces New Record Of Nearly 13 Million Shared Bike And Scooter Trips In 2025

- Chicago: Mayor Brandon Johnson Announces Launch Of New Community Reentry Support Center For Women Returning From Incarceration

- Secondesk Launches Powerful AI Tutor That Speaks 20+ Languages

Retaining the Core Strengths of MCHEdesign

MCHEdesign continues to offer the two modes introduced earlier:

- AI Mode, providing instant coil configuration recommendations based on user input and Kaltra's coil database — optimized for thermal performance, refrigerant compatibility, geometric constraints, and cost-effectiveness.

- Expert Mode, delivering full manual control over coil geometry, layout, and manufacturing-relevant parameters for experienced engineers requiring advanced customization.

Thus, users retain flexibility: they can rely on guided design for fast, standard projects, or employ full manual control when needed.

Designs Aligned With Manufacturing Capabilities

A key enhancement in the new MCHEdesign version is the expanded database of microchannel heat exchanger components, including microchannel tubes, fins, tube-fin-manifold combinations and layout variants.

These components and their validated combinations form the foundation for substantial updates to coil design logic, allowing users to explore a broader range of geometries, thermal configurations, and application-specific optimizations. The software ensures that all selectable options remain compatible with Kaltra's engineering standards and production capabilities.

As a result, users can now configure heat exchanger designs that directly leverage Kaltra's latest production capabilities — ensuring that software-generated designs are not only thermodynamically sound but also fully manufacturable without additional engineering adaptation.

From Design to Deployment — Faster, Safer, Smarter

This new integration streamlines the entire MCHE workflow:

- Design — select application (condenser, evaporator, fluid coil, reversible coil) and enter required parameters.

- Instant Simulation — view performance results immediately.

- Auto-Creation — receive a unique model code, automatically registered in MCHEselect.

- Deep Simulation & Validation — run additional simulations under different conditions, refrigerants, or operating scenarios via MCHEselect.

- Export / Documentation — download design summary, simulation data, and coil specifications for manufacturing or documentation.

This makes MCHEdesign + MCHEselect a complete digital platform for MCHE development — from conception to simulation, validation, and manufacturing.

More on illi News

- Automation, innovation in healthcare processes featured at international conference in Atlanta

- Mayor Brandon Johnson Welcomes Vice President Kamala Harris To Chicago For Martin Luther King Jr. Interfaith Breakfast

- A High-Velocity Growth Story Emerges in Marine and Luxury Markets

- $26 Billion Global Market by 2035 for Digital Assets Opens Major Potential for Currency Tech Company with ATM Expansion and Deployment Plans Underway

- Middle Market M&A Poised for Acceleration in 2026, According to New Survey by Caber Hill Advisors

What This Means for Kaltra Customers

- Faster time-to-market — engineers and OEMs can move from initial concept to validated design in minutes.

- Reduced errors — automated data transfer eliminates manual mistakes and ensures consistency across simulations.

- Flexibility and confidence — whether you need a standard condenser or a complex reversible coil, the integrated platform supports all major MCHE applications.

- Better decision-making — instant feedback on design changes allows rapid optimization for thermal performance, refrigerant selection, geometry constraints, and cost.

Availability

The integrated MCHEdesign platform is available at the Kaltra website. Existing MCHEdesign users will receive automatic access to the updated version. New users can register via the inquiry form.

Source: Kaltra GmbH

Filed Under: Business, Manufacturing

0 Comments

Latest on illi News

- Rande Vick Introduces Radical Value, Challenging How Brands Measure Long-Term Value

- Chicago: Mayor Brandon Johnson Statement On Trump Threatening To Halt Federal Funding For Sanctuary Cities

- Chicago: Mayor Brandon Johnson Statement On Trump Revoking Protected Status For Somali Immigrants

- Mayor Brandon Johnson And The Chicago Department Of Business Affairs And Consumer Protection Reaffirm Support For Small Business Community At The Start Of The New Year

- Lisa Mauretti Launches Peace of Mind Travel Coaching to Guide Fearful Travelers to Discover the World with Confidence

- New Year, New Home: Begin 2026 at Heritage at South Brunswick

- Food Journal Magazine Releases Its 'Best Food In Los Angeles Dining' Editorial Section

- Enders Capital: 25% Gains with Just -0.80% Maximum Monthly Drawdown in Volatile Debut Year 2025

- Chicago: Mayor's Office Of Reentry Releases Inaugural 2025 End Of Year Report

- CES Spotlight Highlights Need for Strategic Review as Throughput Demands Evolve

- ASR Media, Social T Marketing & PR Announce Merger

- $780,000 Project for New Middle East Police Service with Deposit Received and Preliminary Design Work Underway for Lamperd: Stock Symbol: LLLI

- The 3rd Annual Newark Summit for Real Estate, Economic Development & Placemaking Returns February 9th

- Digital Security Deposit Platform Whale Raises $4 Million Seed Round Led by Camber Creek

- Ski Safety Awareness Month highlights why seeing clearly and wearing modern protection matters more than ever

- Vent Pros Expands Operations into Arizona to Meet Growing Demand for Commercial Ventilation and Kitchen Hood Cleaning Services

- Naperville Police Arrest Plainfield Convicted Felon Allegedly in Possession of a Loaded Gun

- Klein Civil Rights Expands with New Offices in New York's Historic Woolworth Building

- Biz Hub Financial Hosts 9th Annual Client Appreciation Event, Awards $1,000 CARES Community Grant

- Green Office Partner Appoints Aaron Smith as Chief Revenue and Growth Officer